Marco Simone. Rome, Italy

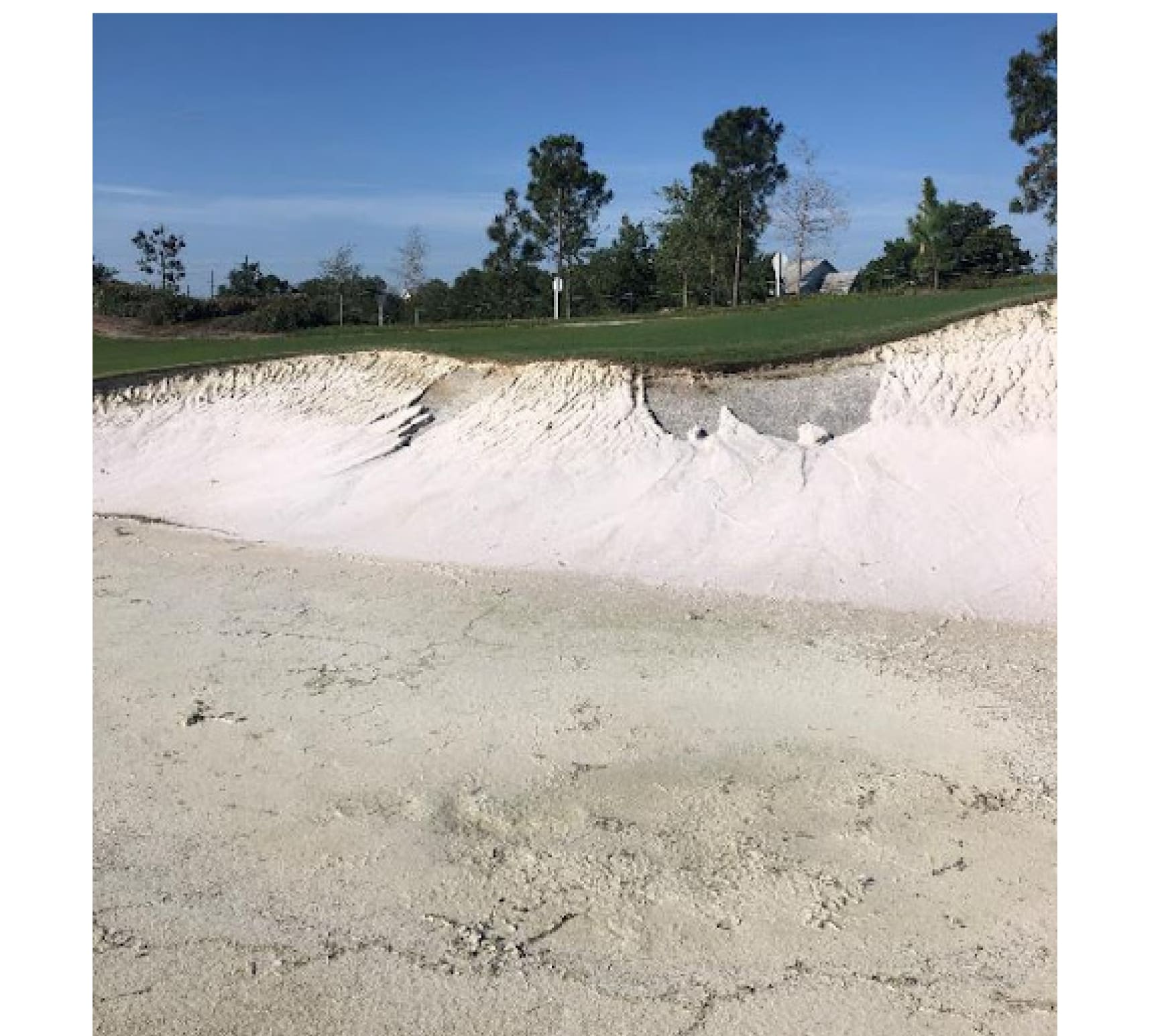

Ask any golf course superintendent or maintenance staff member about the one maintenance issue they absolutely dislike, and the answer is most likely to be: bunker washouts. These occurrences, triggered by heavy rain, can impact playability for days after the rain by causing silt contamination of expensive bunker sand, consuming precious maintenance staff hours for repairs, and the cycle repeats with the next shower.

While bunker washouts can be a frustrating challenge, understanding their root causes is crucial for effective prevention. The fact is that while rain might be the proximate cause of washouts, there are two ultimate causes.

1. Direction of surface water flow: Poor surface drainage and golf course design that directs water into bunkers.

2. Poor internal drainage: Inadequate golf bunker drainage that allows water to build up on the faces, leading to sand movement during rain. Steeply sloped bunkers are especially prone to washouts and contamination.

Frequent washouts not only consume financial resources and demoralize maintenance staff, they have an impact on both short-term and long-term playability of the golf course. Over time, they can also lead to major issues such as sand contamination with soil. This contamination further affects golf bunker drainage, causes compaction, and slows down percolation/infliltration rates of the sand, posing a long-term concern for sand quality, and bunker playability and player satisfaction. The frustrating cycle continues.

So, is there no long-term solution to golf bunker washouts?

There is. While rain may be inevitable, bunker washouts are not. In this blog, we will briefly discuss the various methods golf courses use to prevent bunker washouts first. We will then delve into the details of Capillary Bunkers – a cutting-edge bunker liner that is proven to rapidly drain excess water while retaining adequate moisture in bunker sand, creating optimal playing conditions in golf course bunkers.

One of the most common methods of reducing bunker washouts is installing bunker liners.

These liners, usually made of geotextile or polyethylene, protect the sand from contamination both by the soil on the base and on the faces of bunkers. Effective bunker liners prevent soil from eroding and contaminating the sand. By keeping the soil in place on the face of the bunker, the sand remains clean and water moves rapidly through non-contaminated sand, reducing washouts. The liner also protects soil from clogging the drainage system beneath the bunker.

Despite their benefits, it is common knowledge in the industry that most bunker liners for golf courses are not invincible. Yes, they reduce washouts and contamination but severe storms render most of them useless. Additionally, the problem with conventional bunker liners is that, after a few years, golf courses find that they stop functioning as designed. The liners degrade or rip, losing their efficacy— a significant investment literally gone down the drain.

Another method, recommended by the USGA, involves installing plastic no-dig landscape edging near bunkers to divert surface water away from the sand when rain is imminent. However, in areas or seasons that see regular rainfall, this edging might need to be a permanent installation – not an ideal solution either. Moreover, the process of installing and removing the edging is maintenance-resource intensive, taking the attention of staff away from other areas in the course.

The short answer is no - but it could also be yes. It all comes down to the structure of the liner. To begin with, liners can be divided into three separate categories:

As the above liner types' structure varies, one could typically say the proneness to washouts increase with the degree of impermeability. Liners such as geotextile and to some degree fabric doesn't let water go through the liner itself, but depends on diverting it to the drain lines. This cause two issues:

To conclude, impermeability in a liner increases likelihood of washouts significantly. This is why we recommend either sod or no liner, or preferably a porous aggregate.

This brings us to CapillaryFlow bunker liner technology — Capillary Bunkers. What sets it apart?

Effective moisture control is crucial for bunker performance. As sand dries out on steep bunker faces, the risk of plugged ball lies and washouts during rain events increases. Capillary Bunker liners for golf courses swiftly drain excess rainwater while redistributing moisture to bunker sand during dry weather, retaining optimal moisture in the sand, preventing washouts and migration of sand from faces, and ensuring impeccable playing conditions in any weather and terrain.

But how is it possible for a bunker liner to drain excess water as well as move water upwards to moisten dry sand on the bunker face?

Capillary Bunker liners are made of Capillary Material, a patented pervious cement and polymer material and the only building material to rapidly drain water while also moving it upwards. The Capillary Material’s ability to rapidly drain excess water and move moisture up to the sand in dry weather is one major reason why Capillary Bunkers are a major improvement on conventional bunker liners.

Capillary Wash Box, a value add-on to Capillary Bunker liners, is another CapillaryFlow innovation. The Wash Box enables golf courses to remove contaminants such as algae, debris, silt, clay, and organic pollutants from the bunker sand by simply washing it. In doing so, it preserves the sand’s percolation rate, color, and desired playing properties, while also eliminating the need for frequent sand replacement.

<<<Read more: Sustainable bunker care: Why you should never add more sand to your bunker base to dry it out>>>

This is important because sand can cost between $30 and $200 per ton in the US, depending on location, sand quality, source and transport costs. But its lifespan can be as short as a few months if severe storms occur shortly after the sand is installed. Regularly washing bunker sand with Capillary Wash Box protects a golf course’s investment in sand.

Thousands of bunkers around the world, including many of golf’s top 100 courses, have successfully been renovated with Capillary Bunkers. On top of drastically improving the playability of bunkers, CapillaryFlow clients experience significant maintenance savings and ROI within five year. Learn more about what the ROI of different bunker liner alternatives are here: Bunker Liner ROI

At CapillaryFlow, we're so confident in our bunker liner technology that we offer an industry-leading 15-year structural and drainage performance guarantee on our complete Capillary Bunker system and equestrian sand footing solution, including liner, vaults, and wash boxes.

To recap, here are the benefits of installing Capillary Bunkers.

But don’t just take our word for it. Capillary Bunker liner for golf courses have been installed in over 1,500 venues across the globe, bringing joy to golfers worldwide. This includes some of the world's top 100 golf courses, from Ryder Cup to PGA venues. Below, we provide a number of testimonials from satisfied superintendents and golf course owners.

Testimonials

Case study 1: “Six years on, the bunkers still drain as they did the first day”

Six years after Dubsdread in Orlando, the oldest public course in Central Florida, installed Capillary Bunkers, Superintendent Alan Lichter is extremely happy with their performance.

“I love them,” he said. “They are still draining as they were the first day. We had seven tenths of an inch of rain last night, there’s no water in the bunkers.”

Given the extremes of the Florida climate, Lichter’s bunkers have had to face up to some pretty severe weather – and he says they have come through with colors still flying. Even after Hurricane Ian dumped 11 inches of rain on Dubsdread in September 2022, the CapillaryFlow Bunkers still performed. “It took one person – me – about 12 hours to fix the bunkers after Ian!” said Lichter. “Before we installed the CapillaryFlow bunker liner, it would have needed three guys working solidly for a week.”

Case study 2: “Three hours on the bunkers after a storm, and they’re pristine again”

Even before Jim Sedrel joined as superintendent of Hyperion Field Club in Iowa in 2017, he recalls, the discussion around the club was: “‘Our bunkers are horrid, we need to rebuild them.’”

He soon witnessed the issue first-hand. “Any time we got a two-inch rain, we would be 40-60 man hours putting our bunkers back together,” he said. “There would be silt and soil mixed in with the sand, and the bunkers would be crusty and horrible. It was awful for the members and totally demoralizing for my crew.”

Sedrel realized that the usual fixes were only short-term solutions and advocated for a complete bunker renovation. The club proceeded with a comprehensive bunker renovation and installed Capillary Bunkers in three phases between 2018 and 2022.

Sedrel is very happy with his new bunkers.

“From 40-60 man hours after rain, we’re now at a point where two guys spend three hours on the bunkers, and they’re pristine again,” he said. “We might still see a little bit of washout, but that only happens where, for architectural reasons, we can’t prevent the water coming off a green and into a bunker. We have 100 year old push up greens, and water does sheet off them. The bunkers perform fantastically, and it’s the CapillaryFlow Bunkers liner that we have to thank.”

Case study 3: Capillary Bunker liners: The ‘best product in the market’

At The Breakers Palm Beach, a luxury oceanfront resort in Palm Beach, Florida, the director of golf and grounds, Mark Reid, is using Capillary Bunkers technology and the Wash Box to preserve his sand.

“We use Capillary Bunkers technology to ensure top-quality performance at both our Ocean Course and The Breakers Rees Jones Course,” said Reid. “Previously, when experiencing rain in South Florida, we would have to decontaminate the bunkers every time we had a washout, and once the sand starts to move, the sod would not be far behind. It took more than 200 man hours to put the bunkers back together,” Reid said.

He added: “Upon researching and conducting a trial in 2017, prior to the last Ocean Course renovation, we experienced very little washout after storms once the technology was implemented. I knew then that Capillary Bunkers was the best product on the market to meet our needs.”

Read more testimonials:

Saving money from day one at Oakwing Golf Course, Louisiana

Hurricane can’t hurt new CapillaryFlow Bunkers at Grande Dunes, Myrtle Beach, South Carolina

Saving sand at Royal Marrakech in Morocco

‘The product is amazing – I wish I’d had it years ago’: Kinsale Golf Club, Ohio

‘The results have been consistently excellent’ at Laguna National Golf Resort, Singapore

CapillaryFlow solving bunker problems at Loch Lomond in Scotland

Are you interested in how we can help you reduce washouts, maintenance and have bunkers with optimal performance & washable sand? Contact us!

CapillaryFlow makes it possible to design baseball fields that are able to withstand tough playing conditions as well as ensure a healthy game experience for players.

Our proprietary Capillary Material makes it possible to have a bunker liner that rapidly drain while also retaining adequate sand moisture, creating the perfect playing conditions in golf course bunkers.

The Capillary Hydroponics system enables us to grow strong and durable grass with significantly less maintenance and environmental impact

Optimal riding conditions in any weather by providing a ground material technology offering superior drainage capacity and enabling use of subsurface moisture control - for the optimal footing

Capillary Hydroponic turf lengthens the season with natural strong grass that stays healthier even with a busy schedule

Our Capillary Hydroponics solution turns hardscaped surfaces into breathable, living spaces that augment the positive effects of greenery in urban environments.